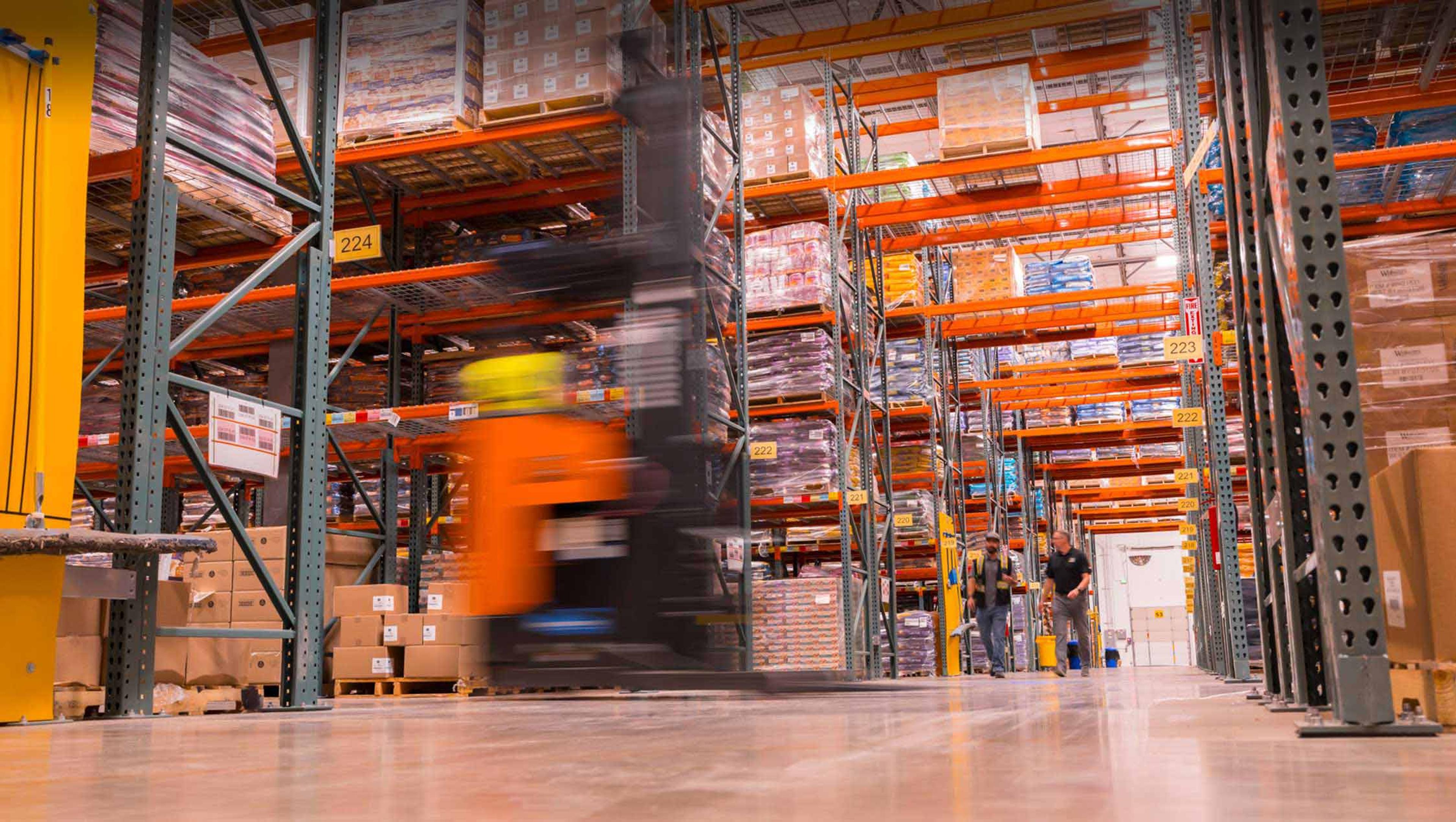

Customized Warehouse Services

Solutions That Offer More Than Just Storage

We can customize warehouse services to match your specific needs, from fulfillment processes to overall supply chain management to implementing technology and everything in between. From our strategic national distribution warehousing and fulfillment locations, you can reach 96 percent of the US population within two days.

With a consistently superior rating from AIB International.

We handle food grade products at the highest standards in the industry and take great pride in the superior cleanliness of our facilities. We have long-standing, strategic experience with customers like Starbucks, Ralston Foods, Mars, Kellogg’s, Dairy Farmers of America, and Nature’s Bakery.

ITS Logistics has long-standing vendor relationships with the following companies: