Optimize Parcel Shipping Strategy with Regional Carriers

Optimizing parcel shipping strategy to reach more customers

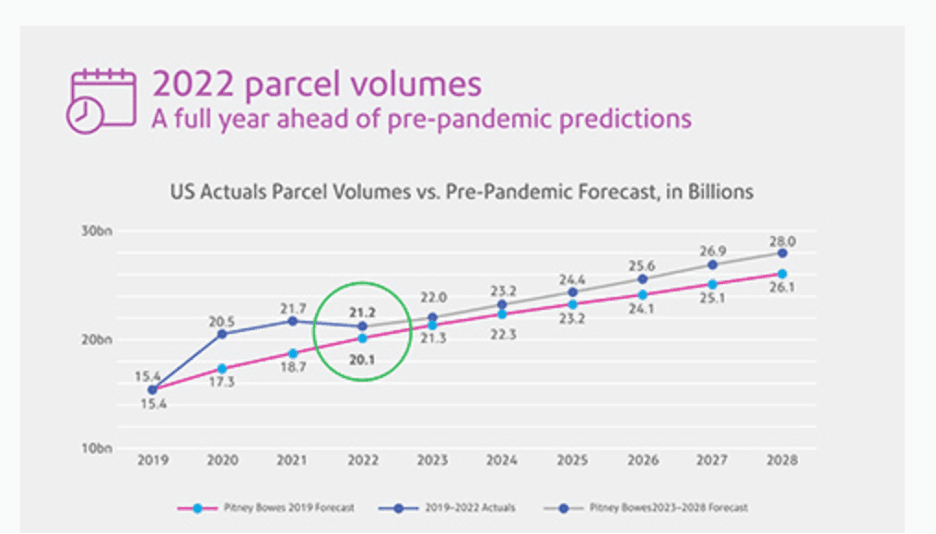

Parcel shipping is expected to grow 5% per year over the next five years, according to an annual parcel shipping index published by Pitney Bowes. Despite a slowdown in 2022, volume has continued to increase at a steady pace over pre-pandemic projections. US parcel volume is expected to reach 28 billion by 2028 according to the report. In 2022 alone, the nation shipped, received, and returned 21.2 billion parcels, which was 1.1 billion shipments higher than projected by pre-pandemic forecasting.

With the explosion of ecommerce over the past couple of years, small parcel shipping carriers have gained ground as major US carriers were inundated with service requests and were forced to reject business. Consumers have begun to pull back on spending due to ongoing inflationary pressures, but small carriers say despite the slowdown there is still plenty of opportunity to gain market share. Carriers have recently reported getting more business from shippers trying to avoid possible labor disruptions over contract negotiations.

Will parcel delivery be hindered by current labor negotiations?

UPS handles about a fourth of packages shipped each day in the US according to the Pitney Bowes index. Many of the parcels belong to small businesses but a looming strike at the end of July could cause major disruptions. The labor contract between the major carrier and 325,000 of its employees is expiring on July 31 and business owners are seeking out potential solutions in case of a strike.

The Postal Service, FedEx, and other third-party shippers are being called upon to ensure that packages can still get to their final destinations. Businesses that have been stretched thin over the past few years are feeling the burden of this latest logistical challenge. Switching to another carrier comes at a cost for some companies that do not have the contractual capacity with additional carriers in place.

Choose a shipping option from three different distribution center campuses

ITS Logistics offers 3.8 million sq. ft. of distribution and fulfillment space across three campuses in Reno/Sparks, NV, Indianapolis, IN, and Dallas/Ft. Worth, TX. The new Dallas-Fort Worth facility serves as the latest location and combined with their existing operations in Reno and Indianapolis, supports efforts to offer national omnichannel distribution and fulfillment services to 95% of the U.S. population in less than two days.

A Q&A with ITS Logistics Distribution + Fulfillment Experts

Kasia Wenker | Director of Supply Chain Solutions

Kasia joined ITS Logistics in 2004 after previously working at Intel and UPS as an industrial engineer. She holds her MBA with a Supply Chain Management emphasis and a Masters in Industrial Engineering.

Jesse Turner | Supply Chain Sales Manager

Jesse joined ITS Logistics as its Supply Chain Sales Manager in March 2022. Prior to that, he worked for 13 years in overseas trade management experience in the container shipping industry.

How do your new locations drive your carrier strategy?

KW: The new locations in Indy and Fort Worth are allowing our team to diversify our carrier offerings and build a fulfillment solution that is precisely built to consumers in a specific market. There is no such thing as one-size fits all in this case. Within each market, we offer custom solutions with both regional and national carriers so that our customers can have the best options possible. For example, when we work with larger carriers in the Indy market, we are close to different shipping hubs and it allows us to zone skip. If we have a customer with products in a specific weight bracket, we explore options with every provider and examine their strengths and weaknesses.

How are zone and transit times impacted by a multi-origin solution vs. a single location?

JT: This really depends on the scale of the business. For a smaller company, a singular solution could make sense for a lower number of units and SKUs that need to be moved. The medium- and large-sized customers typically need at least two to three locations, depending on their product type and how quickly it needs to be moved to its destination. If your product needs to arrive at the destination fast, there is certainly a competitive advantage with a three-node solution that can reach 95% of the US in two days. The cost savings can be immense when it makes sense to split inventory across multiple locations. When it comes to carriers and rates, there are far better pricing options for the last mile when there are a lower number of zones to cross. A shorter route is always going to cost you less.

How can you manage different carriers in different locations?

KW: Every market has different volume fluctuations. In the Midwest, there is a higher population and higher volatility. The West Coast is less dense and more spread our geographically. This also creates a difference in how we work with carriers. Our team works with tens of thousands of shipments per day across many brands. This allows us to help with overall cost, as well as take on the burden of forecasting, equipment planning with carriers on behalf of our customers. . We take our industry knowledge to the table and use it in conjunction with our relationships with our carriers who offer different capabilities to optimize operations.

How does having regional carrier options improve the last mile portion of the supply chain?

JT: Regional providers can typically act nimbly in the solutions that they provide. Their focus on specific regions makes it easier for them to pivot to customers’ needs and offer cost-effective and timely transportation solutions. Add regional with a national coverage carrier and your business can offer customers various last mile solutions.

Is there such thing as too many carriers?

KW: Personally, I don’t find this to be true. There is no reason to stick to one single carrier, negotiating one contract. Each carrier wishes to accumulate the most volume, which can create perceived economies of cost. However, it’s important to examine the strongest attributes of each carrier and negotiate across the board. Splitting volume is no longer a big headache because of today’s advancements in technology. With multiple locations, multiple carriers, and an understanding of volume, we utilize technology that makes management and communication easy. We will always find the best shipping costs and best solutions for each.

Working with a trusted logistics partner

To achieve the most efficient small parcel shipping without incurring abhorrent costs, it may be wise to partner with a trusted logistics provider. With nearly 4 million square feet of distribution space, a footprint in 50 markets in North America, and a knowledgeable team of logistics experts, the team at ITS can offer unique nationwide solutions. Combine any 3PL logistics services like dedicated transportation, intermodal and drayage, distribution and fulfillment, and more to create an integrated and dependable supply chain.

Discover how ITS has helped its customers:

- Caraway Sees 280% Order Volume Increase and Expands into Omnichannel Fulfillment

- Common Challenges, Uncommon Solutions

- ITS Logistics and Starbucks – A Perfect Blend