How to Avoid Lunar New Year Shipping Challenges

Lunar New Year shipping challenges hold the potential to lead to significant supply chain disruptions. Preparing for production slowdowns, limited operations, disrupted schedules, delayed transportation, and impacted rates—including intermodal drayage—will help businesses stay ahead during this important time of year.

Lunar New Year 2024 is right around the corner on February 10 and is one of the most significant festivals of the year in China, marked by a two-week long celebratory period. Production at factories can begin to slow down as early as mid-December in preparation for the festival, and by late January, factories will stop manufacturing altogether. Major Chinese ports typically experience a peak export rush to ship out goods in the weeks leading up to the holiday, with workers starting to leave the week prior and ports switching to limited operational capacity. Workers will return to factories and ports by mid-February, and it typically takes about one to two weeks for operations to return to normal levels.

Some of the challenges that can come during the Lunar New Year/Chinese New Year include:

- Availability of certain products and raw materials may be limited, making it difficult to plan inventory.

- Missed delivery deadlines and increased inventory costs due to factory closures.

- Shortage of labor to load and unload cargo, slowing down the movement of goods.

- As factories close, there can be increased congestion at ports, causing delays in handling and clearing cargo.

- Increased US rail congestion as goods reach the domestic supply chain.

- Higher rates for US carriers as shippers look to over the road modes of transportation to avoid rail congestion.

Challenges Unique to 2024

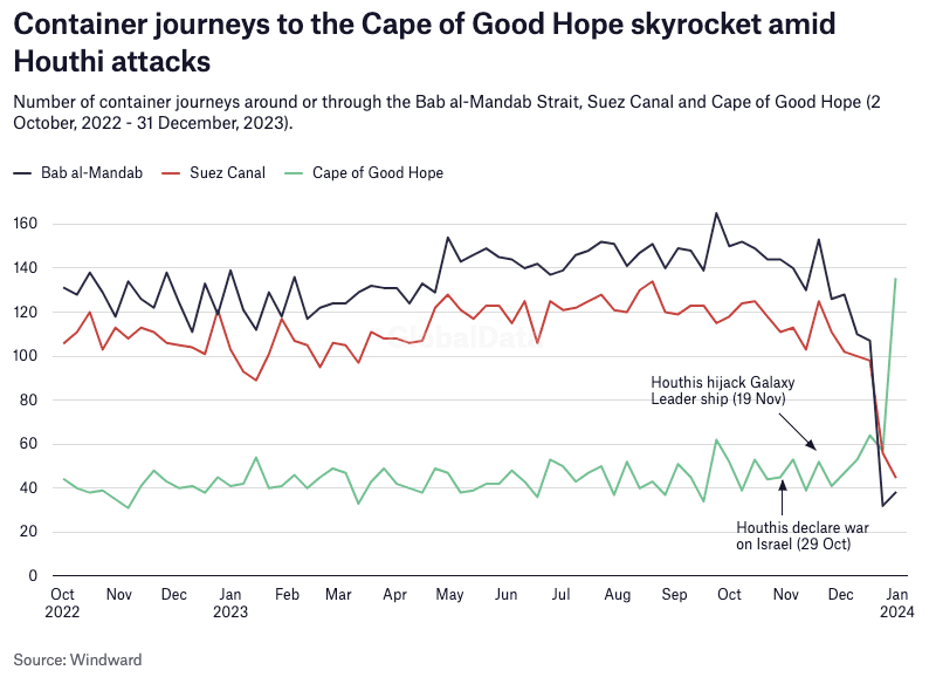

As if typical Lunar New Year shipping challenges weren’t enough, the current diversion of container ships from the Suez Canal paired with drought restrictions on Panama Canal transits have led to a temporary capacity crunch and shipping delays. The unwelcome timing of these disruptions comes during the ramp up ahead of the Lunar New Year holiday. Attacks on commercial ships in the Red Sea have led to 420 container ships, or over one-fifth of global container capacity, being routed around Africa’s Cape of Good Hope as of January 5th, according to Keuhne + Nagel’s vessel tracking.

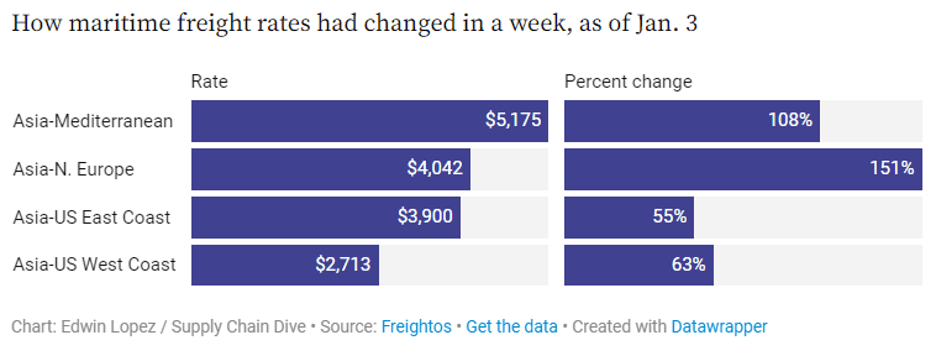

An estimated 30% of worldwide container trade has been impacted by the conflict and the additional one to two weeks in voyage time has significantly increased rates. As of January 3, rates from Asia to the United States West Coast grew 63% to $2,713 per forty foot equivalent unit. Carriers have also implemented surcharges of $500 to $2,700 per container as of mid-January.

The considerably longer transportation times and shipping delay are creating a gap in supply chains and planning for disruptions will help to lessen negative impacts. Caraway Homes is a non-toxic home goods cookware and bakeware company with omnichannel offerings for its customers. Vice President of Operations at Caraway Mark Riskowitz joins ITS Logistics Vice President of Drayage & Intermodal Paul Brashier to share their thoughts and advice on Lunar New Year below.

A Shipper’s Perspective: Understanding Lunar New Year Challenges

How does 2024 Lunar New Year inventory build out compare to the holiday peak in Q4?

“The 2024 Lunar New Year poses distinct challenges for the global supply chain, especially with the ongoing Red Sea crisis. As we know, Lunar New Year creates factory closures and creates disruptions in shipping schedules, affecting production and logistics lead times. With the hundreds of vessels rerouted from the Suez, capacity continues to tighten and lead times will be amplified as the year progresses. In contrast, the Q4 holiday peak sees increased consumer demand that places immense pressure on the domestic US supply chain. Buildouts for inventory require meticulous planning and considerations on their respective parts of the supply chain.” - Mark Riskowitz, VP, Operations Caraway

Is there anything different about this year’s inventory strategy specific to Lunar New Year?

“Given the above, importers are ordering up and becoming more conservative in global lead times and with their supply chain cost assumptions. The events of the past few years have served as a strong series of indicators and data for what to expect in the coming months.” - Mark Riskowitz, VP, Operations Caraway

What are the biggest challenges shippers will face this Lunar New Year?

“There could be challenges soon with increased volumes at US ports. Increased transpacific volumes due to seasonal Lunar New Year restock paired with diverted volumes to avoid the crisis in and around the Suez will stress underutilized West Coast ports, especially in the Los Angeles/Long Beach terminals. Shifting trade lanes from East Asia to US East Coast are increasing demand to transpacific lanes and increasing rates. We’ve also seen additional volume from the East and Gulf Coast ports return to the West Coast ports.

As all this freight arrives to the West Coast, the volume that was diverted from the Suez will have to be transported via rail to reach East Coast markets. That significant amount of volume is expected to cause congestion at rail ramps throughout the US as infrastructure absorbs this change to the supply chain.” - Paul Brashier, VP of Drayage & Intermodal ITS Logistics

What steps can be taken to avoid disruption and mitigate supply chain risk in the face of these challenges?

“There are considerable challenges for the intermodal and ocean container network on the way. We are advising shippers to take a balanced approach to bookings in the near term. If you have containers that are needed quickly, book them to the US West Coast for rail service to other markets. If critical, transload and one-way truck them to their destinations. Booking containers for JIT supply chains and hot SKUs from SE Asia to the US West Coast will allow you to avoid the Suez Canal diverted vessels.

The most important lesson we can learn during the post-pandemic congestion crisis is that shippers should hedge their points of entry into North America. Take advantage of multiple modes and trade lanes, avoid moving all freight through forecasted congested entry points and modes of transportation.” - Paul Brashier, VP of Drayage & Intermodal ITS Logistics

Build a more resilient supply chain with ITS Logistics

ITS Logistics has decades of experience providing creative solutions that help customers maximize their supply chain through every economic condition and potential delays. With the highest level of service, unmatched industry experience and work ethic, and a laser focus on innovation and technology– the team at ITS strives to improve the quality of life for its partners by delivering excellence at every turn.

ITS Logistics maintains a high standard for distribution and fulfillment supply chain management:

- 99.6% ASN Timeliness

- 99.8% Load Quality

- 99.8% ASN Accuracy

- 99.9% On-Time Shipping

- 99.4% Fill Rate

- 99.3% Pallet & Carton Labeling

Reach out to learn more about ITS Logistics and find a creative logistics solution that will work for your business.